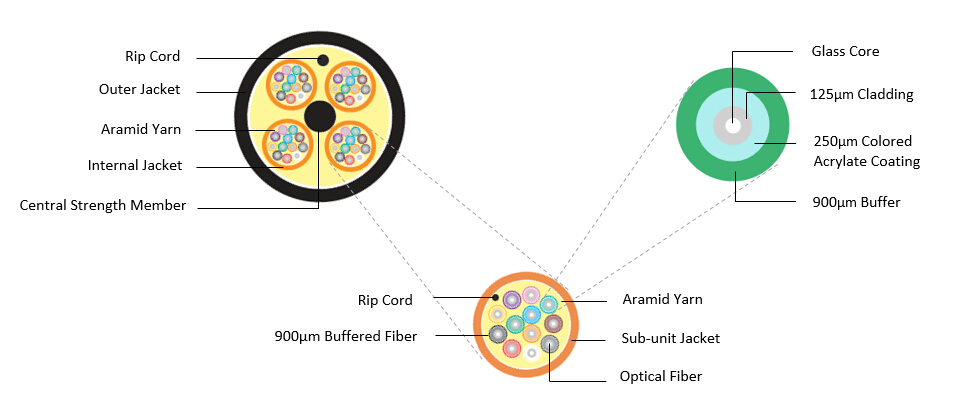

Tight-buffered construction uses 900μm buffered fibers. The core is protected by two-layer coating. The first is plastic and the second is waterproof acrylate. The core of the cable is never at risk of exposure, unlike the loose-buffered cable which can escape its confines. Fibers are surrounded by dielectric strength members (FRP) and are protected by a rugged polyurethane outer jacket and provides superior environmental and mechanical protection. The fiber count for tight-buffered fiber cable varies from 1 to 144 fibers, but generally cables with 2, 6, 12, 24 fibers are the most commonly used. Larger fiber counts such as 48 fibers, 96 fibers and 144 fibers are also available for specific applications.

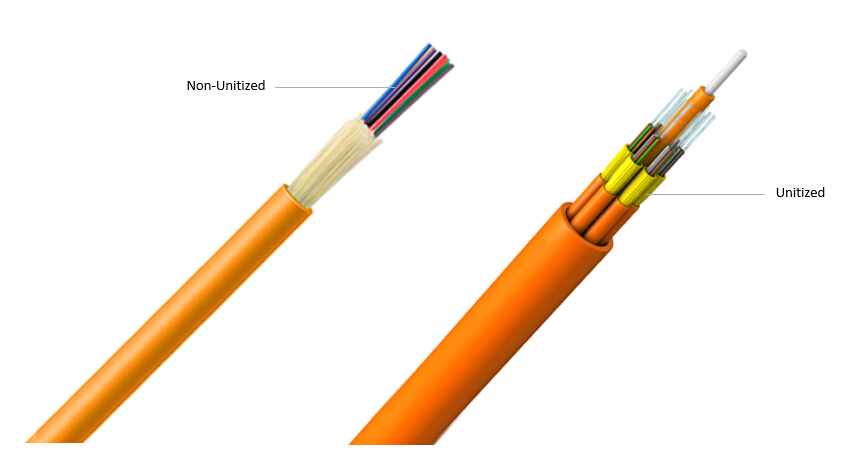

Tight-buffered cable can be unitized or non-unitized. The only difference between them is that the former is unitized with individual jacket. The unitized design makes the bundled fibers easier to install and manage than non-unitized. Conversely, non-unitized cable is designed just with a single outer jacket, but it is more flexible in cabling and has much smaller packages and cost advantages.

汉信

汉信