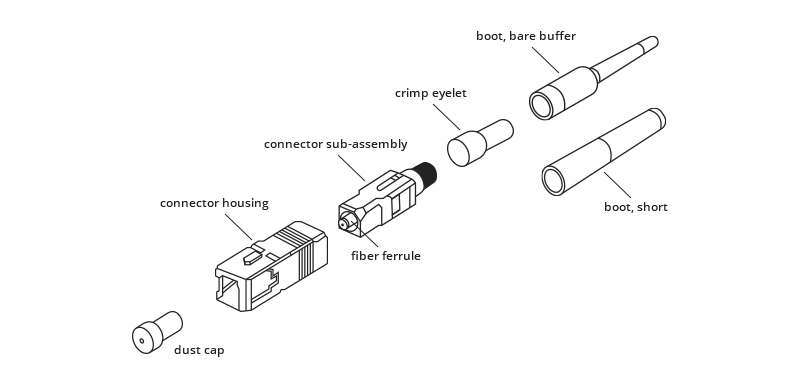

For an optical connector design, there are five key and important components: the fiber ferrule, the sub-assembly body, the connector housing, the fiber cable, and the stress relief boot. We’ll take an SC connector for example to illustrate the structure of the fiber optic connector.

- Fiber Ferrule

- The SC fiber optic connector is built around a long cylindrical 2.5mm diameter ferrule, made of ceramic (zirconia) or metal (stainless alloy). A 124um-127um diameter high precision hole is drilled in the center of the ferrule, where stripped bare fiber is inserted through and usually bonded by epoxy or adhesive. The end of the fiber is at the end of the ferrule, where it is typically polished smooth.

- Sub-assembly Body

- The ferrule will be assembled in the SC sub-assembly body that has mechanisms to hold the cable and fiber in place. The end of the ferrule is out of the sub-assembly body in order to mate with another SC connector inside a mating sleeve (i.e. adapter or coupler).

- Connector Housing

- The ferrule will be assembled in the SC sub-assembly body that has mechanisms to hold the cable and fiber in place. The end of the ferrule is out of the sub-assembly body in order to mate with another SC connector inside a mating sleeve (i.e. adapter or coupler).

- Fiber Cable

- Fiber cable and strength member (aramid yarn or Kevlar) are crimped onto the connector sub-assembly body with a crimp eyelet, increasing the strength of the mechanical handling of the connector while protecting the fiber inside at the same time.

- Stress Relief Boot

- Stress relief boot covers the joint between the connector body and fiber cable to protect the fiber cable from mechanical damage. Stress relief boot designs are different for 900um tight-buffered fiber and 1.6mm-3mm fiber cable.

汉信

汉信